Storage of Fuel🔗

Pressurization and boil-off🔗

This next section is about observing the temperature and pressure evolution of a filled hydrogen tank. When ambient heat ingresses through the tank insulation, the temperature will increase and so will the pressure with thermal expansion.

Overview🔗

- Setup system boundaries.

- Define Experiments for Foam and Vacuum.

- Analyze tank conditions when there is heat ingress during storage (no fuel injection or extraction) at ground conditions (storage).

System Setup🔗

-

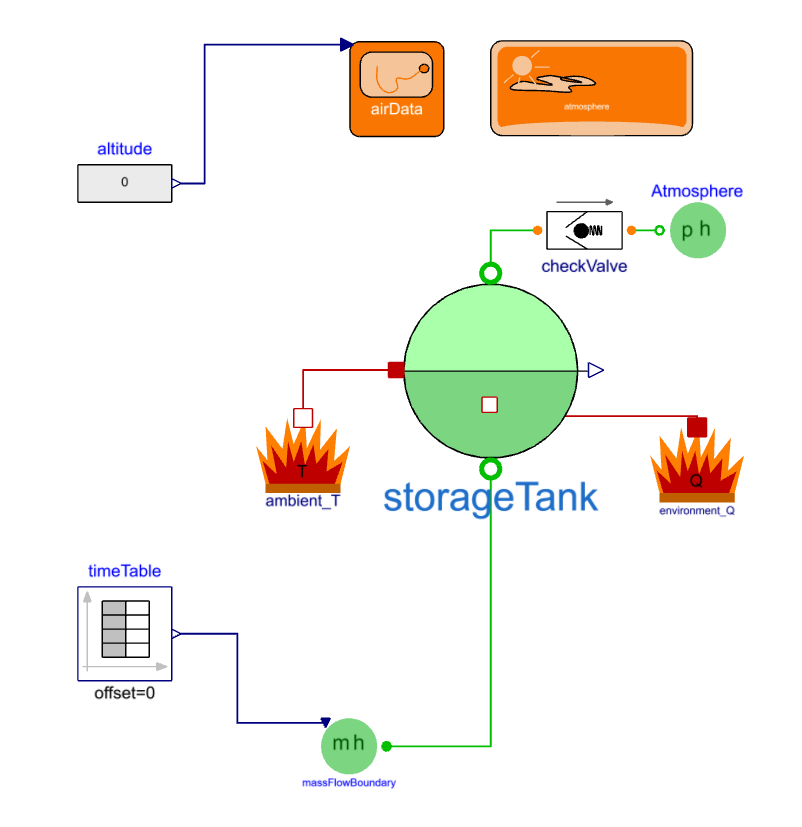

Create a new model in the Experiments package by duplicating Workspace.Experiments.TankFilling and call it TankPressurization. This will carry over the Experiment definitions and View already set up.

-

For this experiment, we are not filling the tank so the related parameters that were added for TankFilling can be deleted:

- M_liq_fill

- t_fill_start

- fill_rate

- t_fill

-

For the timeTable, change the parameter table to [0,0; 1,0] so that no flow will go to or from the massFlowBoundary.

-

For the storageTank,

-

enable_liquidHeatPort = true, to expose thermal port in the liquid volume.

-

initFromLevel = false, so that the tank is initialized by the V_liq_start based on massHydAvail.

-

-

Add in Modelon.ThermoFluid.Sources.Environment_Q and connect to the storageTank liquid heat port (heat_liquid).

Experiment Definitions🔗

Foam232 and MLI232 experiment definitions were carried over from refueling section through the duplication step. They will be reused since they already contain the tank geometry. The “MultiRate” experiment with the variable fill_rate can be deleted since those filling parameters have already been removed from the model.

-

In the Experiments Foam232 and MLI232, provide a value for massHydAvail since the storageTank is being initialize by the intermediate volume parameter being computed at initialization. The value should be the same as the mass used to size the tanks with 13% of the volume reserved for vapor.

- Foam232 massHydAvail = 13620 kg

- MLI232 massHydAvail = 10220 kg

-

Change the StopTime for both experiments to 86,400 s and Interval to 172.8 s so that there will be 500 data points.

-

Simulate both experiments and check the Results.

-

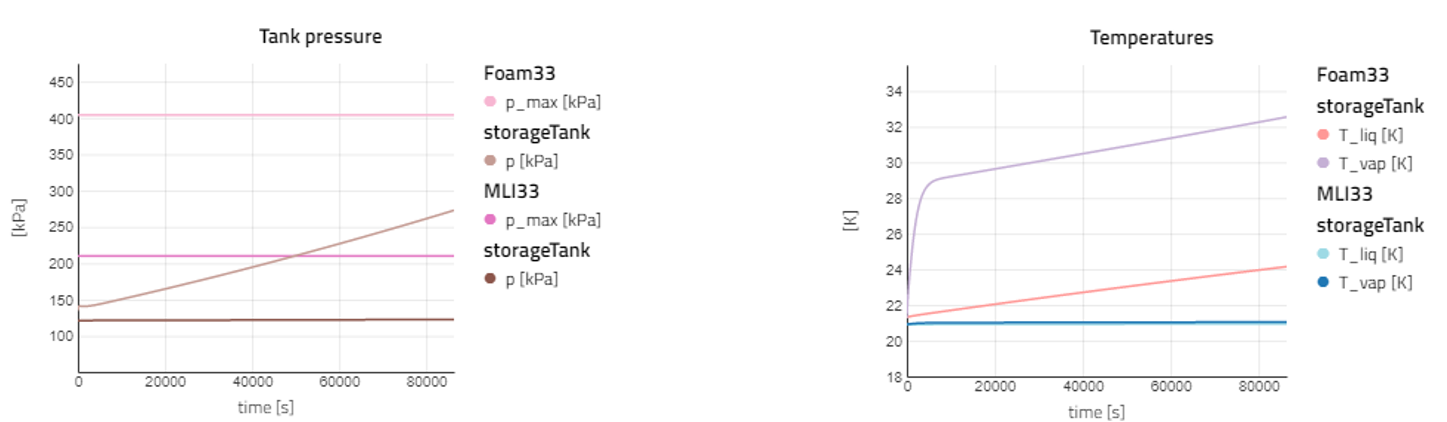

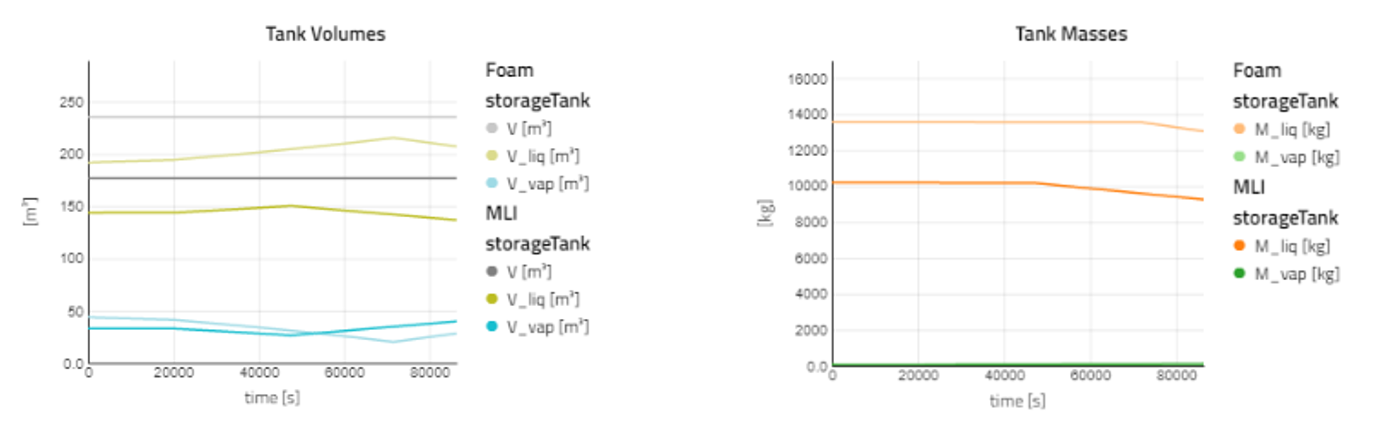

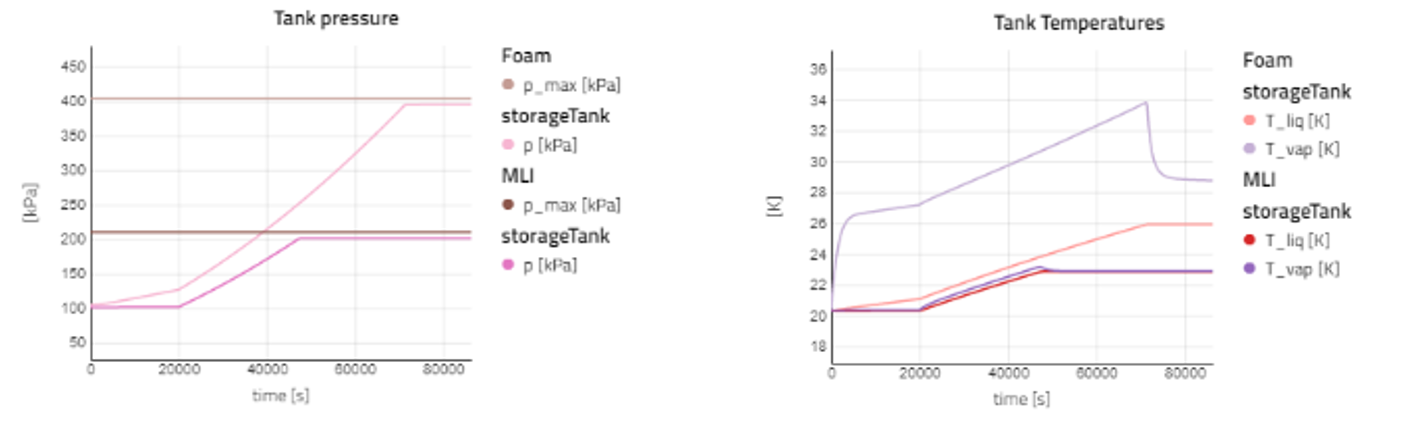

Over the 24 hr simulation, the MLI tank temperatures stay relatively the same, whereas the temperature of the liquid in the foam tank steadily rises and the vapor temperature is approximately 8 degrees higher.

-

The tank pressure rises but no venting is needed. Perhaps at longer storage times.

-

-

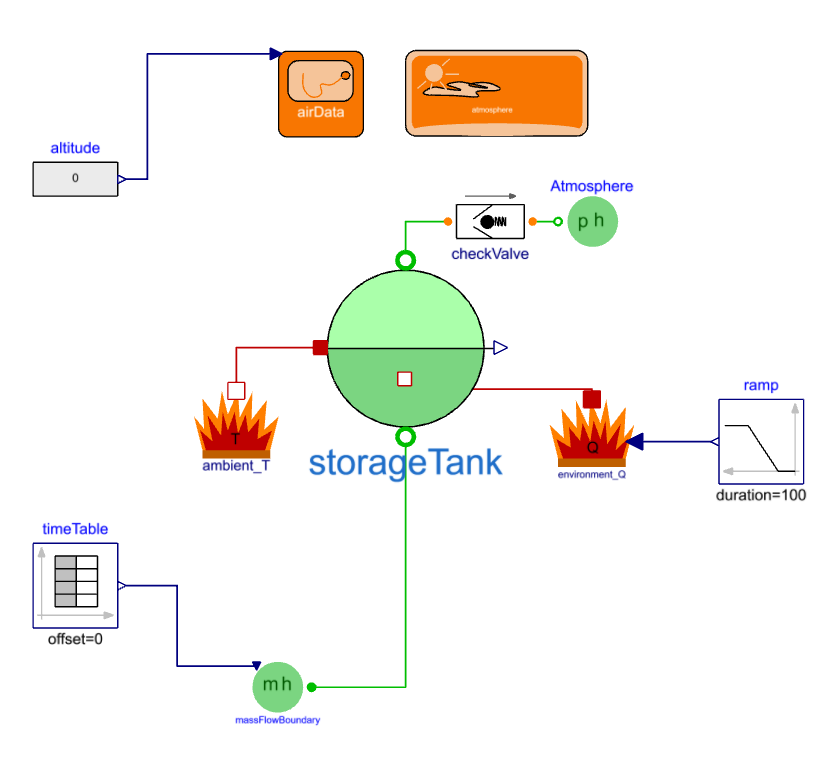

Go back to the Modeling Mode and in environment_Q change paraOption_Qflow to true. Connect it to a Modelica.Blocks.Sources.Ramp.

-

In the ramp, change the height to 1e4, duration of 100 s and startTime to 20000 s. This will cause heat to be added to the liquid in the tank ramping from 0 W to 10 kW over 100 s starting at 20000 s.

- Since the change was made to the model, switch back to Experiment mode and run the experiments for Foam and MLI again.

-

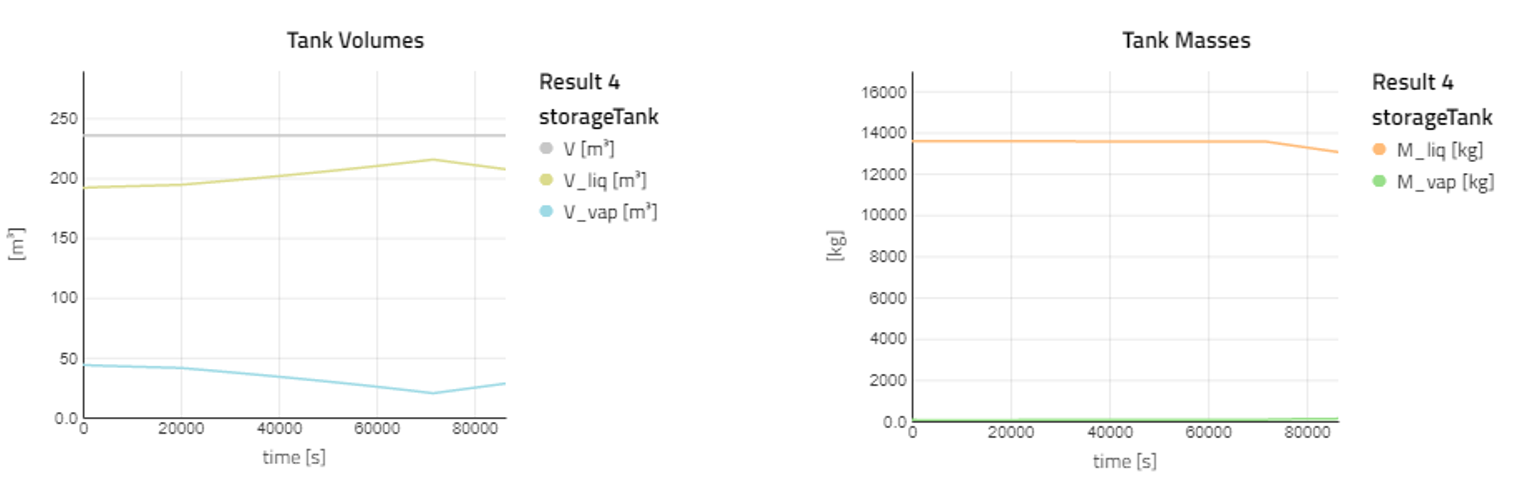

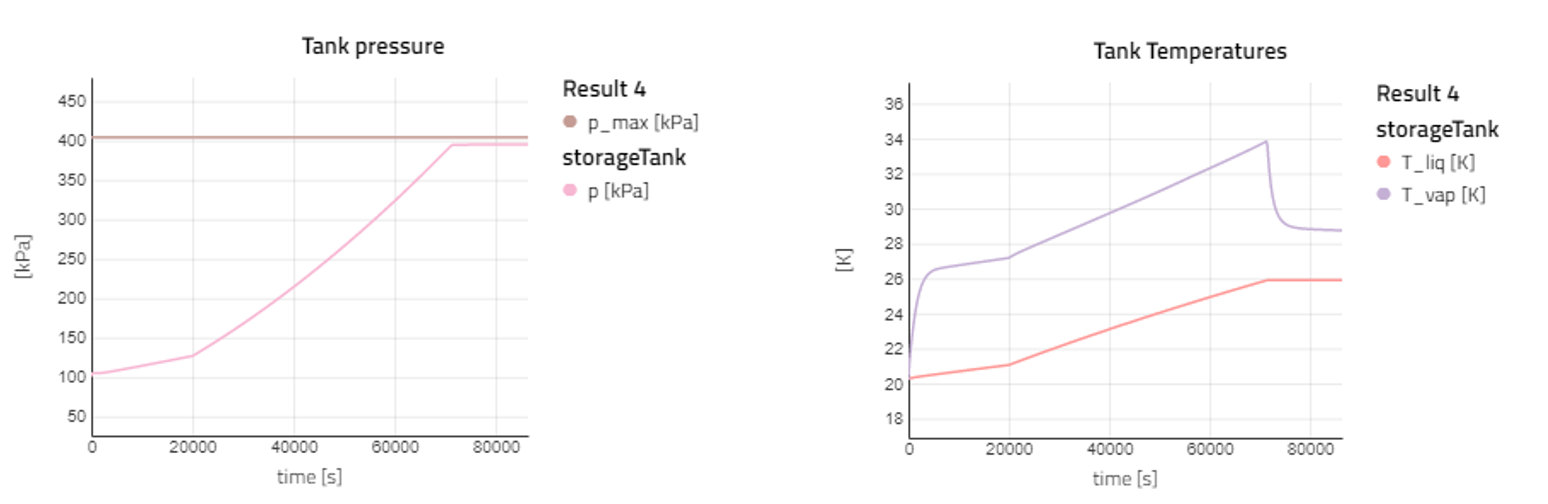

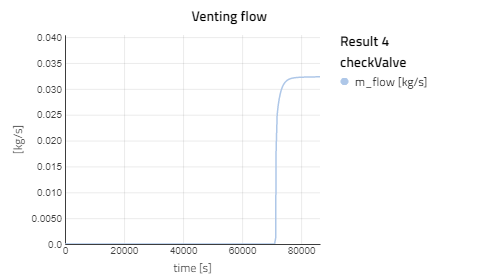

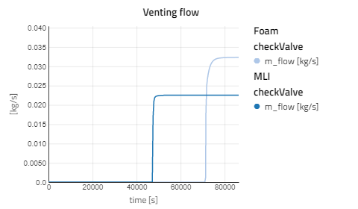

Looking at the results for the Foam tank, the additional heat ingress cause the pressure and temperature to rise faster than with just the ambient heat ingress. At time = 70,500 s the pressure reaches the point where the checkValve is opened to allow vapor to vent off and avoid reaching the maximum operating pressure. With the valve open, the pressure settles at 395 kPa and the venting rate settles around 0.03 kg/s.

-

When compared to the MLI tank, the maximum pressure is lower, so venting begins sooner, but the temperature of the vapor does not rise as high.

Suggestion🔗

- Multirun with different heat flow into the liquid heat port.

- Flight conditions when alt > 0.