Experiment 2: Flow Simulation - dp_pump Sweep

With the flow balancing problem solved, a small domain exploration of the pump pressure can be performed through a multi-run experiment.

To understand the experiment setup, navigate to the predefined experiment "Experiment 2 - Flow Simulation - dp_pump Sweep".

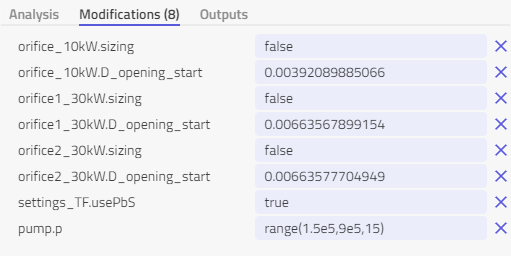

The following modifications are applied to the model for domain exploration:

Note the following points based on the experiment setup.

- The sizing parameter is set to false for each orifice which then requires a value for D_opening_start to be specified rather than a design flow rate.

- The calculated values for the previous Sizing experiment are given as inputs for D_opening_start in each orifice.

- Rather than simulating multiple experiments for different pump pressures, the range operator is used to instruct the compiler to run a multi-run simulation for the values of pump.p ranging from 1.5 bar to 9 bar over 15 equidistant values for the pump pressure.

Tip: In Modelon Impact, the results of one steady-state simulation experiment can be used to initialize a new experiment. This feature can be particularly useful for larger systems to avoid the manual copy and pasting of many result values into a new experiment. In this case the values for D_opening_start have already been applied to the experiment as modifiers based on results of the orifice sizing experiment.

Results

To interpret the results of this Flow Simulation Experiment:

- Simulate the experiment in steady state.

- Rename the result file to appropriately to match the experiment name.

- Once the result is selected, enable the system view Experiment 2&3 Flow Simulation Analysis under views to display two plots.

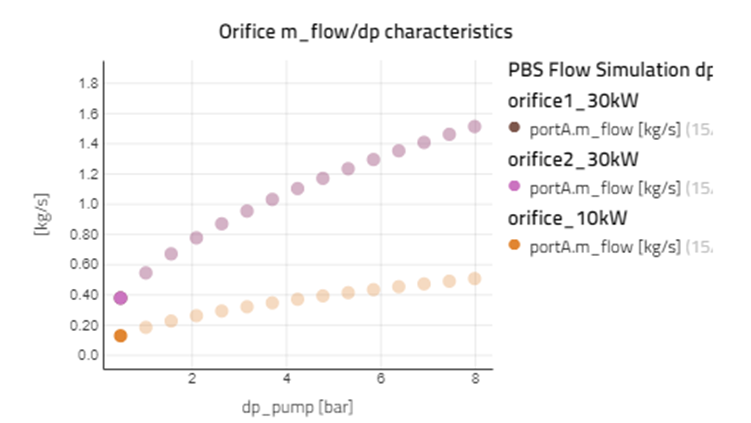

The plot below shows the flow rates in each branch as a function of pressure difference across the pump where dp_pump = p.pump - p.pressureSink.

Figure 4: Results from flow simulation Experiment 2- mass flow rate in each branch over a range of values for dp_pump

One can observe a non-linear correlation between the pressure drop and flow rates in each branch based on the Hagen-Poiseuille equation which relates pressure drop to flow rate in an enclosed circular pipe for laminar flow. The smaller orifice diameter for the left-side branch results in a less sensitive correlation between flow rate and pressure difference compared to the middle and right-hand branches which have a larger orifice diameter.

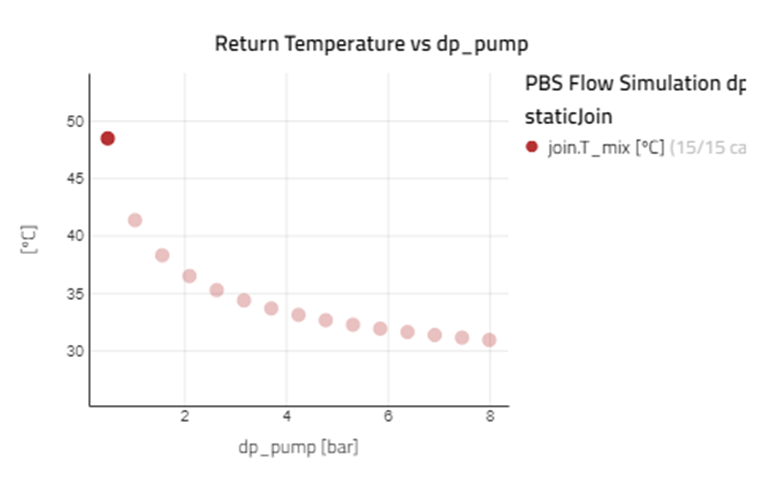

The second plot below depicts the correlation between dp_pump and the temperature at the component staticJoin where the three branches merge after carrying the heat loads upstream. As expected, for higher values of dp_pump (and therefore higher flow rates), the mix temperature in the return flow is lower as more heat can be evacuated at higher flow rates.

Figure 5: Results from flow simulation experiment 2- return temperature over a range of values for dp_pump